| 公司名: | 佛山宝尔特斯密封技术有限公司 |

| 联系人: | 袁生(先生) |

| 电话: | 0757-63262514 |

| 手机: | 13632397087 (打电话请说明在"中国泵阀制造网"看到享优惠) |

| 传真: | 86-0757-82822046 |

| 地址: | 广东佛山 禅城区工业路2号联达液压厂内4楼 |

| 邮编: |

轴用斯特封 GSJ

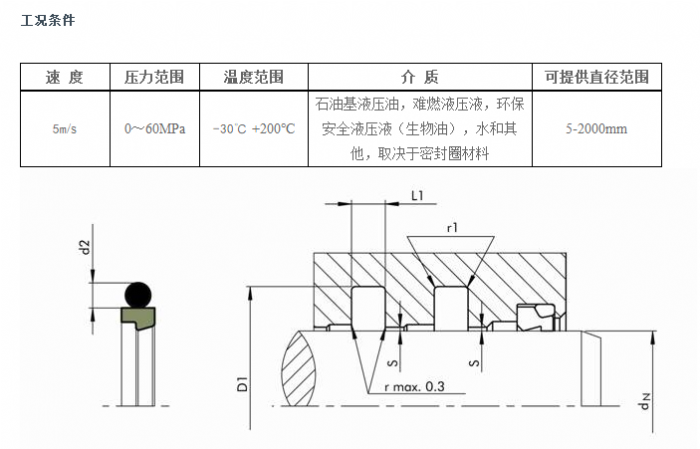

应用范围

液压往复运动系统。在高、中、低压及重载,高频工况下的密封场合非常出色。适合各种行程及范围较广的流体和高温场合,可适用较大的活塞杆间隙。例如在推土机,挖掘机,锻压机,陶瓷压砖机,轧钢机,伺服阀及机床等。

-----专注·专业做好密封 宝尔特斯密封欢迎您来电咨询!!

标准材料

密封环:填充聚四氟乙烯F-PTFE 或聚氨酯PU

0形圈:丁腈橡胶NBR 或氟橡胶FKM

特点

-良好的动静密封性能

-抗挤出性好

-尺寸稳定,不受温度影响

-不会发生困压,可多只串联安装

-对强冲击压力有优异的缓冲作用

-摩擦力小,无爬行,粘滞现象

-耐腐蚀性强

-沟槽结构简单

-寿命长

-有无润滑均可工作

-安装简便

标准规格:

| 型号 | 沟槽尺寸 | |||||||

| d | D | H | B | R | E | O型圈 | ||

| 0~20MPa | 20~40MPa | |||||||

| GSJ-8*3.2 | 8 | 15.5 | 3.2 | 3.75 | 0.5 | 0.6~0.3 | 0.3~0.1 | 10.6*2.65 |

| GSJ-10*3.2 | 10 | 17.5 | 3.2 | 3.75 | 0.5 | 0.6~0.3 | 0.3~0.1 | 12.5*2.65 |

| GSJ-12*3.2 | 12 | 19.5 | 3.2 | 3.75 | 0.5 | 0.6~0.3 | 0.3~0.1 | 14*2.65 |

| GSJ-14*3.2 | 14 | 21.5 | 3.2 | 3.75 | 0.5 | 0.6~0.3 | 0.3~0.1 | 16*2.65 |

| GSJ-16*3.2 | 16 | 23.5 | 3.2 | 3.75 | 0.5 | 0.6~0.3 | 0.3~0.1 | 19*2.65 |

| GSJ-18*3.2 | 18 | 25.5 | 3.2 | 3.75 | 0.5 | 0.6~0.3 | 0.3~0.1 | 20*2.65 |

| GSJ-20*4.2 | 20 | 31 | 4.2 | 5.5 | 0.7 | 0.6~0.3 | 0.3~0.2 | 23.6*3.55 |

| GSJ-22*4.2 | 22 | 33 | 4.2 | 5.5 | 0.7 | 0.6~0.3 | 0.3~0.2 | 26.5*3.55 |

| GSJ-25*4.2 | 25 | 36 | 4.2 | 5.5 | 0.7 | 0.6~0.3 | 0.3~0.2 | 28*3.55 |

| GSJ-28*4.2 | 28 | 39 | 4.2 | 5.5 | 0.7 | 0.6~0.3 | 0.3~0.2 | 31.5*3.55 |

| GSJ-30*4.2 | 30 | 41 | 4.2 | 5.5 | 0.7 | 0.6~0.3 | 0.3~0.2 | 34.5*3.55 |

| GSJ-32*4.2 | 32 | 43 | 4.2 | 5.5 | 0.7 | 0.6~0.3 | 0.3~0.2 | 36.5*3.55 |

| GSJ-35*4.2 | 35 | 46 | 4.2 | 5.5 | 0.7 | 0.6~0.3 | 0.3~0.2 | 37.5*3.55 |

| GSJ-36*4.2 | 36 | 47 | 4.2 | 5.5 | 0.7 | 0.6~0.3 | 0.3~0.2 | 41.2*3.55 |

| GSJ-40*6.3 | 40 | 55.5 | 6.3 | 7.75 | 1.2 | 0.8~0.4 | 0.4~0.2 | 43.7*5.3 |

| GSJ-45*6.3 | 45 | 60.5 | 6.3 | 7.75 | 1.2 | 0.8~0.4 | 0.4~0.2 | 50*5.3 |

| GSJ-50*6.3 | 50 | 65.5 | 6.3 | 7.75 | 1.2 | 0.8~0.4 | 0.4~0.2 | 53*5.3 |

| GSJ-55*6.3 | 55 | 70.5 | 6.3 | 7.75 | 1.2 | 0.8~0.4 | 0.4~0.2 | 58*5.3 |

| GSJ-60*6.3 | 60 | 75.5 | 6.3 | 7.75 | 1.2 | 0.8~0.4 | 0.4~0.2 | 63*5.3 |

| GSJ-63*6.3 | 63 | 78.5 | 6.3 | 7.75 | 1.2 | 0.8~0.4 | 0.4~0.2 | 67*5.3 |

| GSJ-65*6.3 | 65 | 80.5 | 6.3 | 7.75 | 1.2 | 0.8~0.4 | 0.4~0.2 | 69*5.3 |

| GSJ-70*6.3 | 70 | 85.5 | 6.3 | 7.75 | 1.2 | 0.8~0.4 | 0.4~0.2 | 75*5.3 |

| GSJ-75*6.3 | 75 | 90.5 | 6.3 | 7.75 | 1.2 | 0.8~0.4 | 0.4~0.2 | 80*5.3 |

| GSJ-80*6.3 | 80 | 95.5 | 6.3 | 7.75 | 1.2 | 0.8~0.4 | 0.4~0.2 | 85*5.3 |

| GSJ-85*6.3 | 85 | 100.5 | 6.3 | 7.75 | 1.2 | 0.8~0.4 | 0.4~0.2 | 90*5.3 |

| GSJ-90*6.3 | 90 | 105.5 | 6.3 | 7.75 | 1.2 | 0.8~0.4 | 0.4~0.2 | 95*5.3 |

| GSJ-95*6.3 | 95 | 110.5 | 6.3 | 7.75 | 1.2 | 0.8~0.4 | 0.4~0.2 | 100*5.3 |

| GSJ-100*6.3 | 100 | 115.5 | 6.3 | 7.75 | 1.2 | 0.8~0.4 | 0.4~0.2 | 106*5.3 |

| GSJ-105*6.3 | 105 | 120.5 | 6.3 | 7.75 | 1.2 | 0.8~0.4 | 0.4~0.2 | 109*5.3 |

| GSJ-110*6.3 | 110 | 125.5 | 6.3 | 7.75 | 1.2 | 0.8~0.4 | 0.4~0.2 | 112*5.3 |

| GSJ-120*6.3 | 120 | 135.5 | 6.3 | 7.75 | 1.2 | 0.8~0.4 | 0.4~0.2 | 122*5.3 |

| GSJ-125*6.3 | 125 | 140.5 | 6.3 | 7.75 | 1.2 | 0.8~0.4 | 0.4~0.2 | 128*5.3 |

| GSJ-130*6.3 | 130 | 145.5 | 6.3 | 7.75 | 1.2 | 0.8~0.4 | 0.4~0.2 | 132*5.3 |

| GSJ-140*6.3 | 140 | 155.5 | 6.3 | 7.75 | 1.2 | 0.8~0.4 | 0.4~0.2 | 145*5.3 |

| GSJ-150*6.3 | 150 | 165.5 | 6.3 | 7.75 | 1.2 | 0.8~0.4 | 0.4~0.2 | 155*5.3 |

| GSJ-160*6.3 | 160 | 175.5 | 6.3 | 7.75 | 1.2 | 0.8~0.4 | 0.4~0.2 | 165*5.3 |

| GSJ-180*6.3 | 180 | 195.5 | 6.3 | 7.75 | 1.2 | 0.8~0.4 | 0.4~0.2 | 185*5.3 |

| GSJ-200*8.1 | 200 | 221 | 8.1 | 10.5 | 1.5 | 1.0~0.6 | 0.6~0.4 | 206*7 |

| GSJ-220*8.1 | 220 | 241 | 8.1 | 10.5 | 1.5 | 1.0~0.6 | 0.6~0.4 | 230*7 |

| GSJ-240*8.1 | 240 | 261 | 8.1 | 10.5 | 1.5 | 1.0~0.6 | 0.6~0.4 | 243*7 |

| GSJ-250*8.1 | 250 | 271 | 8.1 | 10.5 | 1.5 | 1.0~0.6 | 0.6~0.4 | 256*7 |

| GSJ-260*8.1 | 260 | 284.5 | 8.1 | 12.25 | 1.5 | 1.0~0.6 | 0.6~0.4 | 265*7 |

| GSJ-280*8.1 | 280 | 304.5 | 8.1 | 12.25 | 1.5 | 1.0~0.6 | 0.6~0.4 | 290*7 |

| GSJ-300*8.1 | 300 | 324.5 | 8.1 | 12.25 | 1.5 | 1.0~0.6 | 0.6~0.4 | 307*7 |

| GSJ-320*8.1 | 320 | 344.5 | 8.1 | 12.25 | 1.5 | 1.0~0.6 | 0.6~0.4 | 325*7 |

| GSJ-340*8.1 | 340 | 364.5 | 8.1 | 12.25 | 1.5 | 1.0~0.6 | 0.6~0.4 | 345*7 |

| GSJ-350*8.1 | 350 | 374.5 | 8.1 | 12.25 | 1.5 | 1.0~0.6 | 0.6~0.4 | 355*7 |

| GSJ-360*8.1 | 360 | 384.5 | 8.1 | 12.25 | 1.5 | 1.0~0.6 | 0.6~0.4 | 365*7 |

| GSJ-380*8.1 | 380 | 404.5 | 8.1 | 12.25 | 1.5 | 1.0~0.6 | 0.6~0.4 | 387*7 |

| GSJ-400*8.1 | 400 | 424.5 | 8.1 | 12.25 | 1.5 | 1.0~0.6 | 0.6~0.4 | 412*7 |

| GSJ-420*8.1 | 420 | 444.5 | 8.1 | 12.25 | 1.5 | 1.0~0.6 | 0.6~0.4 | 425*7 |

| GSJ-450*8.1 | 450 | 474.5 | 8.1 | 12.25 | 1.5 | 1.0~0.6 | 0.6~0.4 | 462*7 |

| GSJ-460*8.1 | 460 | 484.5 | 8.1 | 12.25 | 1.5 | 1.0~0.6 | 0.6~0.4 | 462*7 |

| GSJ-500*8.1 | 500 | 524.5 | 8.1 | 12.25 | 1.5 | 1.0~0.6 | 0.6~0.4 | 500*7 |

| GSJ-520*8.1 | 520 | 544.5 | 8.1 | 12.25 | 1.5 | 1.0~0.6 | 0.6~0.4 | 530*7 |

| GSJ-550*8.1 | 550 | 574.5 | 8.1 | 12.25 | 1.5 | 1.0~0.6 | 0.6~0.4 | 560*7 |

| GSJ-580*8.1 | 580 | 604.5 | 8.1 | 12.25 | 1.5 | 1.0~0.6 | 0.6~0.4 | 580*7 |

| GSJ-600*8.1 | 600 | 624.5 | 8.1 | 12.25 | 1.5 | 1.0~0.6 | 0.6~0.4 | 600*7 |

| GSJ-620*8.1 | 620 | 644.5 | 8.1 | 12.25 | 1.5 | 1.0~0.6 | 0.6~0.4 | 630*7 |

| GSJ-650*9.5 | 650 | 678 | 9.5 | 14 | 2 | 1.2~0.8 | 0.8~0.5 | 670*8.6 |

| GSJ-680*9.5 | 680 | 708 | 9.5 | 14 | 2 | 1.2~0.8 | 0.8~0.5 | 700*8.6 |

| GSJ-700*9.5 | 700 | 725 | 9.5 | 14 | 2 | 1.2~0.8 | 0.8~0.5 | 720*8.6 |

| GSJ-750*9.5 | 750 | 778 | 9.5 | 14 | 2 | 1.2~0.8 | 0.8~0.5 | 770*8.6 |

| GSJ-780*9.5 | 780 | 808 | 9.5 | 14 | 2 | 1.2~0.8 | 0.8~0.5 | 800*8.6 |

| GSJ-800*9.5 | 800 | 828 | 9.5 | 14 | 2 | 1.2~0.8 | 0.8~0.5 | 820*8.6 |

| GSJ-850*9.5 | 850 | 878 | 9.5 | 14 | 2 | 1.2~0.8 | 0.8~0.5 | 870*8.6 |

| GSJ-900*9.5 | 900 | 928 | 9.5 | 14 | 2 | 1.2~0.8 | 0.8~0.5 | 920*8.6 |

| GSJ-950*9.5 | 950 | 978 | 9.5 | 14 | 2 | 1.2~0.8 | 0.8~0.5 | 970*8.6 |

| GSJ-1000*9.5 | 1000 | 1028 | 9.5 | 14 | 2 | 1.2~0.8 | 0.8~0.5 | 1020*8.6 |